Chains are sturdy and reliable machine components which transmit power through forces from one place to another. They are most commonly used as a cost-saving component of power transmission machines for heavy loads and low speeds and often used to transmit power to the wheels of a vehicle, particularly in motorcycles and bicycles, however, they also apply in other variety of machines. A flexible as belts and as positive as gears, chain offer design flexibility, convenience, resistance to shock loads, simplicity of installation and dependability.

Roller chains are the most common types of chain where efficient, economical power transmission is required. Roller train drives possess outstanding advantages as compared to other medium of transmitting power. Although roller chains are made of materials with long lasting durability, there are other factors that are the key to maximizing your chain's service life and minimizing operational costs.

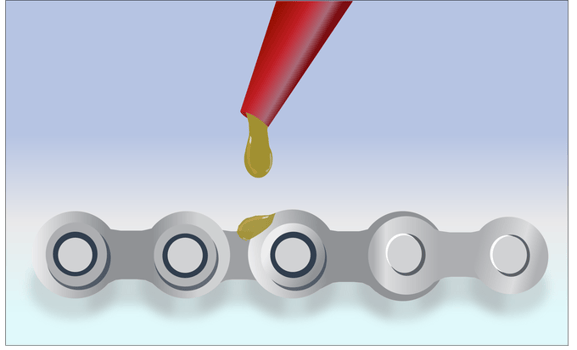

The Importance of Proper Lubrication

Roller chains and drives need to be protected against dirt and moisture to run smoothly.

To achieve optimum chain life, and reduce the rate of wear, comes from ensuring effective lubrication. Not only does proper lubrication slows the rate of wear, it also provides hear dissipation and cushion impact loads.

It is highly recommended that you use a good grade of petroleum-based oil without additives. Some additives may leave a gum deposit or varnish which prevents the oil from entering chain joints. Heavy oils and greases should be avoided, as these are generally too stiff to enter the chain surface.

Replace Worn Sprockets and Check Their Alignment

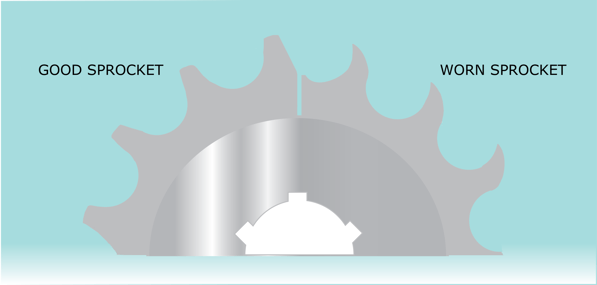

Worn sprockets are one of the largest culprit of premature wear. Running new chains on worn sprockets, akin to running worn chains on new sprockets, increases chain load amounts at the sprocket level. A worn sprocket can cause rapid chain wear and should be replaced as soon as possible.

The misalignment of sprockets is another aspect in early chain wear. When replacing sprockets, be sure to also check the alignment of the fitting of both the sprockets and the shafts. A precise alignment of shafts and sprocket tooth faces provide uniform distribution of load across the entire chain width and contributes substantially to achieving maximum life. If sprockets are not on the same plane and angled relative to each other, the wear rate may increase considerably due to the extra forces on the chain.

There are also other factors that can affect chain wear rate:

1) Improper Chain Tension

Tightening a chain more than necessary in an application directly affects the rate of wear. Therefore, avoid over-tension in order to increase chain life.

2) Incorrect Chain Size

An improperly selected chain size will not have the capacity to transfer the target load, therefore it can result in rapid wear.

Proper installation and regular maintenance of your chain drive are essential steps to prolong the life expectancy of chains. SLSPro provides services that can help you with these crucial times, assisted by our experienced team of engineers.

If you would like to know more information about chain products, please click below: