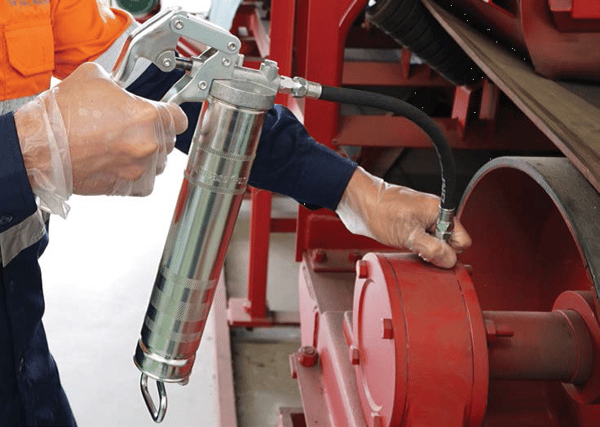

Choosing the right grease for your bearings is essential to prevent premature failure, but let's not forget the importance of grease guns too.

Grease guns are designed to help with machine reliability; However, if improperly used, it can turn into a lethal weapon, causing the failure of your equipment. We have prepared some practical tips on how to make the best use of your grease guns.

| Caution: |

| Sometimes, air can get trapped in the head chamber in grease guns. This may prevent the grease guns from dispensing grease. |

Here are 2 easy ways on how you can release the trapped air:

1. Depending on the type of grease gun, you can use the lever to allow air to escape through the button valve or through the small hole that's exposed when the head is loosened from the barrel. After the air has escaped, the resistance in the lever will change as grease enters the pumping chamber.

2. Alternatively, strike the gun's plunger handle on a hard surface several times while holding the gun vertically with the head pointing upwards.

| Caution: |

| When handling motor bearings, extra care can go a long way and improve the lifespan of your bearings. |

Tips for Greasing Motor Bearings:

Below are three simple tips on how to grease your motor bearings:

1. Leave some time for grease to distribute

When applying grease to an electric motor bearing with a grease gun, allow some time for the grease to disperse- ideally, take around 3 to 5 seconds per shot from the grease.

2. Stop adding grease when cavity is full

If grease appears around the shaft or outside the purge line, stop adding the grease immediately. This means the cavity is full.

3. Give it some time for excess grease to purge

After adding up to the maximum volume of fresh grease, leave out the purge plug for 10 to 30 minutes to allow any excess grease to purge before reinstalling the plug in the purge port or port. It is not a problem, though, if the grease does not purge.

With a better understanding on handling grease guns, you will be able to enhance the performance of your equipment and increase the effectiveness of your operation.

Have questions about grease and grease guns?

Apart from providing grease guns and related products, our team of technical experts are here to help you using the best practices of grease gun, providing your machinery with more efficiency and reliability. Get in touch with us, click on the button below: