Lubrication is the control of friction & wear by the introduction of friction reducing film between moving metal surface that are in contact. The function of lubrication is to:

- Reduce friction

- Prevent wear

- Protect equipment from corrosion

- Prevents entry of contaminates

Why is lubrication important?

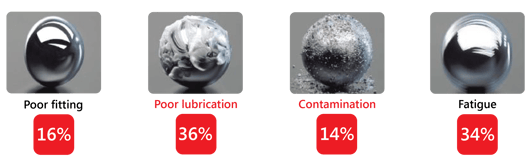

According to a MIT study, it is calculated that 6 – 7% of America’s Gross Domestic Product (GDP) is spent repairing damages caused by poor lubrication practices. This could be worse in other parts of the world. The failures are caused by:

As shown above, 50% of premature bearing failures are due to lubrication or contamination issues with examples such as:

- too much or too little lubrication,

- not often enough,

- wrong type of lubrication, contamination of lubrication with water, air, particles, etc..

- cross-contamination (i.e. mixing of incompatible lubricants)

The effects of poor lubrication practices are detrimental to an entire industrial operation as lubrication has a significant influence on maintenance cost. Lubrication failure leads to component failures, which results in overtime labour to undergo repair work. In turn, these maintenance costs escalate and losses would be substantial.

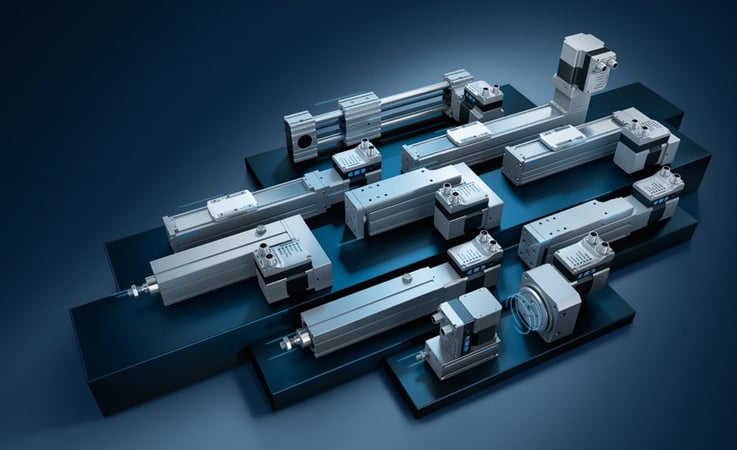

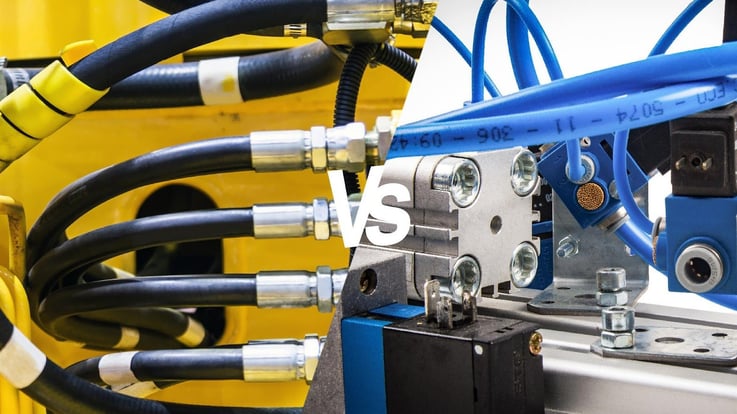

Ways of lubrication

There are two types of lubrication method:

Manual lubrication – the use of a grease gun or portable grease control valve which is connected to the lubrication grease nipple & injecting an uncontrolled amount of lubricant to the bearing.

Automatic & manual centralised lubrication systems – a system that delivers controlled small amounts of lubricant on a regular basis to multiple grease point locations on an equipment/machine while in operation.

You can check out part 2 of this article "Why Automatic Lubrication Systems Are a Must on Today's Machinery?" to find out more about the benefits of an automatic lubrication system.

Interested to find out more?

Click on the button below to get in touch with our team to request for more information.

JSG Industrial Pte Ltd, Singaporeis the authorized distributor for Lincoln & SKF Lubrication Systems. Together with SLS a combined experience of 115 years, we work together towards a common goal to deliver solutions to our customers with our expertise, passion and commitment.

JSG Industrial Pte Ltd, Singaporeis the authorized distributor for Lincoln & SKF Lubrication Systems. Together with SLS a combined experience of 115 years, we work together towards a common goal to deliver solutions to our customers with our expertise, passion and commitment.