Couplings are mechanical elements used to connect two drive elements together for the transfer of torque from one element to another. A coupling connects both elements, usually shafts, that are in rotational movement, while also allowing a certain degree of misalignment, end movement, or both.

In this segment of our Power Transmission series, we will discuss the common mistakes that you can avoid to ensure an extended life span of your coupling.

1. Selecting the wrong coupling

Couplings are a critical component in delivering overall system performance and on many occasions, motion-control couplings are selected a little too late in the design process and when this happens, the couplings often do not meet the system requirements. As a result, changes have to be made to the system in order for the couplings to work correctly. Not only does this take up time, which is a crucial factor of system efficiency, it also costs money to restructure the system. Therefore, it is essential that couplings are selected early along the process to avoid these costs.

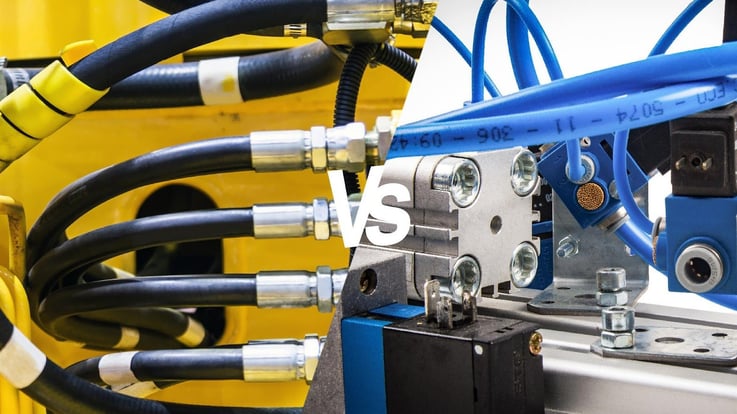

There are a number of design aspects to consider when selecting couplings, which include misalignment, torque inertia, rpm, shaft mounting, environment, space limitations and service factors. These criteria must be addressed in the selection process.

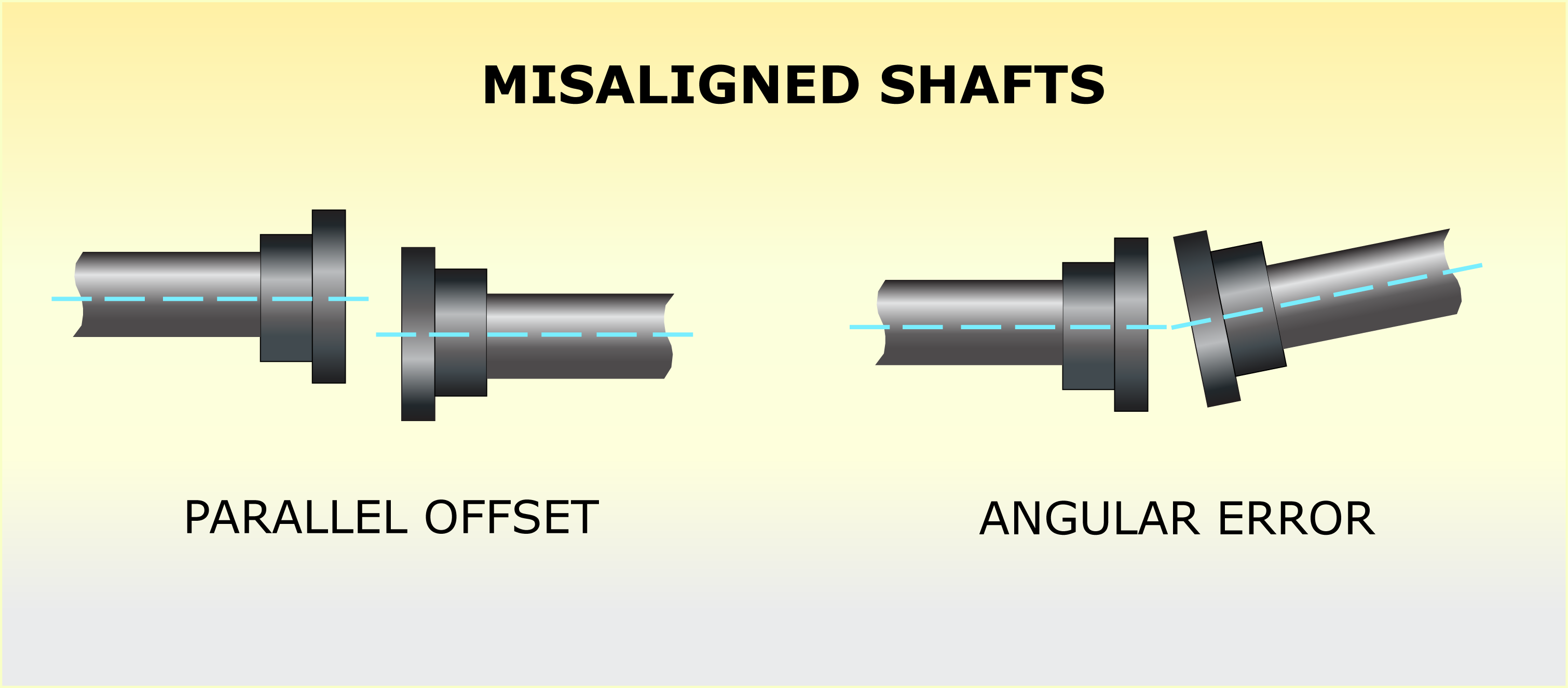

2. Alignment Error

Misalignment creates the load that can surpass coupling specifications and is one of the most common factor for coupling failure and the forces generated by misalignment impact not only the coupling, but can also fail prematurely in other machinery components such as bearings, seals, and gears etc.

Excessive misalignment between joined shafts is one of the most common reasons for coupling failure. Misalignment that produces load exceeding coupling specifications can accelerate wear. All flexible shaft couplings are designed to allow some misalignment and varying degrees of flex, therefore it is extremely important to know the allowable flex for this coupling.

When misalignment beyond the specification occurs, you should first attempt to realign the shafts, and then select the appropriate coupling.

3. Improper Installation

Far too often a coupling is installed hastily or many overlook on the manufacturer specifications, not thinking that it is important, however it is a costly mistake that can result in premature failure. Even with the best design effort and attention when selecting a coupling, the system would not suffice if the coupling is installed improperly.

Prior to installation, make sure that coupling and shafts are well prepared as shown in the checklist below:

1. Cleaning mating parts and oiling shafts gently

2. Check that any misalignment between shafts is within the coupling's rating

3. Tightening fasteners in the correct order and to the torque requirement

During the installation, be sure to center any misalignment along the length of the coupling and avoid installing the coupling too far left or right of the center line. Couplings should be installed in a stress-free condition, they should not be compressed or stretched.

Remember to always refer to the specific manufacturers instructions when performing a coupling installation.

4. Poor System Maintenance

The efficiency and effectiveness of your system cannot be achieved without proper maintenance. Therefore, it is very important to undergo regular checks and look out for any anomalies during operation.

If coupling fails, engineers should document the system conditions at failure. This allows for appropriate corrective action, up to and including specifying a different coupling that better meets the needs of the application.

At SLS, we offer an array of couplings products for a wide range of applications. For reliability, quality and fuss-free maintenance, our Engineering team and technical staff at SLS come up with coupling solutions to increase your equipment uptime and lower your total cost of ownership.

Book a free consultation with us today!