Almost everyone has experienced the power of hydraulics simply by riding in or driving a car. There are many areas where hydraulics play a role in industrial power, as it joins mechanical and electrical power as the world’s leading systems.

Hydraulic power tools stand out as some of the best because of their efficiency. They are especially powerful systems for supporting industrial business where load requirements can have quick and dramatic shifts.

How Hydraulics Work

Hydraulics offer the ability to both transmit sustainable power and to control it.

Hydraulic power is used in various industries, from coal mining and excavating to amusement parks and agriculture. It’s so useful in so many areas because it is based in Pascal’s Law, which states that:

"A change in pressure at any point in an enclosed fluid at rest is transmitted undiminished to all points in the fluid."

This is the basic principle behind hydraulic systems.

Unlike gas, which is burned up, the liquid used in hydraulics remains in consistent quantities. The energy exerted is spread, not lost, making it very efficient.

It’s not only efficient, but powerful. Hydraulics are able to provide the massive force necessary to power wind turbines or diggers, just as they can bring your car to a halt. You can also harness the power of hydraulics in hand-held power tools, like breakers, saws, or drills.

This efficiency makes them a reliable product for all of your power tool needs.

Caring for Your Hydraulics

Hydraulic tools are a smart and efficient way to harness this efficient power. The immense power you get from these tools requires that they are met with the same respect.

The internal workings of hydraulic tools are susceptible to contamination. Dust and particles can get into the chamber, causing sludge that can not only affect your tool’s power but eventually lead to its breakdown. Proper cleaning of your hydraulic tools is integral to ensuring they remain reliable for your work.

System failure might not be completely avoidable, but with proper cleaning it can be avoided for many years. You can also check out a blog that we've written in the past, "5 Most Common Hydraulic Equipment Mistakes to Look Out For"

Here, we've provided just a few helpful and easy tips that can improve the strength and life of your hydraulic tools:

Tips to Keeping Hydraulic Tools Healthy

1. Keep Them Clean (from contaminants)

The prime reason for premature breakdown of hydraulic tools is contamination. This amounts for 90% of tool failure.

Another great thing about hydraulic tools is their general safety and simplicity. You get high power with just a few easy-to-grasp components. Since you can understand where the power comes from, you can keep a better read on its health levels and act accordingly.

Extra effort should be taken to avoid contamination whenever and wherever possible. Below are some good practices to minimize or eliminate potential contamination while storing, handling, assembling and using hydraulic system components:

Ports & Fittings:

- Port plugs should remain in components and hoses until ready to use

- Use care in removing port plugs so that plastic does not shear off in threads

- Fittings being screwed into the port should be kept clean and lubricated

Assembly & Storage:

- Reservoirs should be pickled treated with rust protection and sealed until used. At the time of use, the rust protection must be flushed out

- Never use shop air to blow out a tube, hose or reservoir as the air supply might not be "clean" air

- Hydraulic assembly areas should be free of airborne contaminants

- If components are stored in a cold environment, be sure to remove any condensation that may occur as the components warm up

- If storage is prolonged, components may need to be rust proofed

Fluids:

- Hydraulic fluid should be filtered to ISO 18/13 (according to the ISO Cleanliness Code) or better for initial fill

- Water and hydraulic fluids do not mix- water is considered a foreign chemical contaminant

- Any surface in contact with hydraulic fluids must be clean and dry

- Hydraulic assembly areas should be free of airborne contaminants

Cleaning it properly is very important to the health and safety of the tools. With proper care, your hydraulic tools can last for years. Make the time to do a proper cleaning to ensure that dirt and contamination doesn’t begin deteriorating your tools.

2. Use Them Properly

Hydraulic power tools are designed to last. To ensure a long and productive life, always remember do the following:

- Follow the manufacturer’s guidelines

- Read the instruction manual

- Never exceed tool’s rated capacity

Misuse and abuse are strong causes for tool failure. Using hydraulic tools without a full operational understanding may be well-intended but can lead to devastating results for your tools or the handler. It is also equally important to consider the safe operation of hydraulic tools to prevent injuries or casualties.

3. Stick to Scheduled Maintenance

Periodic cleaning and proper use of your tools will help to preserve their power. However, you shouldn’t wait until you notice contamination or reduced functionality before you do a clean.

Each component should get attention yearly. You may also want to consider developing a fluid-analysis program, so that contamination comes to the spotlight quickly. Contamination of any kind signals that it’s time for a clean.

It’s very important to be committed to this schedule to ensure safety and efficiency of your hydraulic tools. This cleaning process should involve changing the hydraulic oil, and cleaning out the hoses, pistons and pumps. This continued check-up can be an integral portion of keeping your tools healthy for the long run.

Get the Most Out of Your Hydraulics

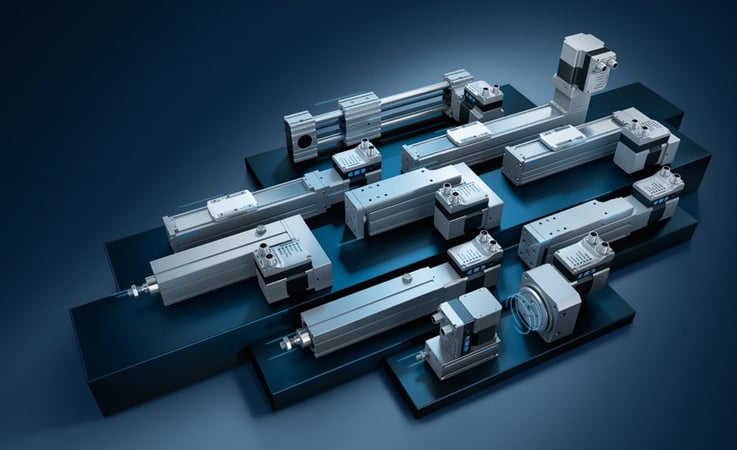

At SLS, we partner with the global leader in hydraulics to bring you an integrated system of sustainable and reliable hydraulic tools in Singapore. We committed to not only serving high-quality hydraulic tools, but also offering support. When you buy our products, you are also gaining access to the experts in the hydraulic field. They are available to assist after the sale with engineering solutions or technical support, so you can get the most out of your hydraulics.

If you have any questions on the health and life of your hydraulic tools, we are here to help. Knowing everything you need about the tool’s functionality and processes can ensure that you get the most of your purchase and your business processes can run safely and efficiently. If you would like to learn more, click on the button below: