A bearing's lifespan depends on a few factors:

- Mounting and Dismounting

- Bearing Maintenance

- Frequent Lubrication

In this post, we are going to focus on the mounting of bearings and learn about the different methods of bearing installation

What is Mounting?

Mounting refers to the fitting of ball bearings both onto a shaft and into a housing.

| Did you know? Around 16% all premature bearing failures are the result of fitting damage. This is often because maintenance technicians are not trained in the correct methods or do not have access to the proper tools. |

The methods of mounting significantly affect bearings performance and therefore, the process require a careful application to ensure that they perform to their fullest potential. There are several types of mounting methods:

Mounting Methods

1. Cold Mounting

- Mechanical

- Drive-up method

- Oil injection method

2. Hot Mounting

- Induction heater

- Heating cabinets & electric hot plates

Before we dive into the bearing installation process, it is important to understand a couple of basic terms:

Interference fit: A type of fit in which the minimum diameter of the shaft should always greater than the maximum size of the hole.

Bearing Internal Clearance: (Radial and axial internal clearance) The distance one bearing ring can be moved relative to the other.

| Internal clearance affects service life |

| Bearing internal radial clearance is usually greater than the operational internal radial clearance due to the effects of interference fits and thermal expansion. |

| Bearings are normally selected with the aim of running with operational radial internal clearance slightly greater than zero. |

Before You Mount

We suggest that you do some preparation work before you start on the mounting process. Here are 2 steps you will need to perform to make your job easier:

1. Before Mounting

- Check dimensional and form accuracy of associated components

- Document values in report form

2. Prepare Associated Components

- Assemble all components needed for mounting

- For tight fit, coat seats with a thin layer of light oil

- For loose fit, coat the bearing seats with anti-fretting agent

Now we've covered the groundwork, let's dive into the 2 types of mounting methods:

1. Cold Mounting

Cold mounting is the method of mounting bearings without heat. The technique uses both mechanical and hydraulic methods.

As mentioned above, there are 3 types for cold mounting method and each is being used in for different application:

i. The Mechanical Method

To start off, here are some essential tools for mounting bearings mechanically:

- Spanner

- Socket

- Fitting tool (TMFT)

- Dead blow hammer

Application

This is a useful technique when driving small bearings with a cylindrical bore onto a shaft or into a house.

ii. Drive-up Method

The drive-up method is a hydraulic technique. Some important tools used in this technique are:

- Lock nut spanner

- Hook spanner

- Hydraulic nut and pump

The hydraulic method is much more powerful as compared to the mechanical method. If used incorrectly, the hydraulic tools might remove the bearing's radial clearance.

Application

This is the preferred technique for driving up medium sized to large bearings with a tapered bore onto a tapered seat. Hydraulic tools are used in this method.

iii. Oil Injection Method

This oil forms a film between the two surfaces, which reduces friction, making mounting easier. Still, note that for this procedure, both the ducts and the grooves should already be in place, as part of the shaft design. If they aren’t, it is necessary to machine the oil grooves, feed channels and threaded connections into the shaft or sleeve before performing the oil injection.

Application

This method also uses hydraulic tools to facilitate the mounting of medium and large size bearings with tapered bore by injecting a thin film of oil between the inner ring bore and it's seating.

2. Hot Mounting

Hot mounting uses heat to expand the bearing, relive interference fits and allow bearings to easily slide onto their mating component.

Let's look at the different methods for mounting bearings using heat:

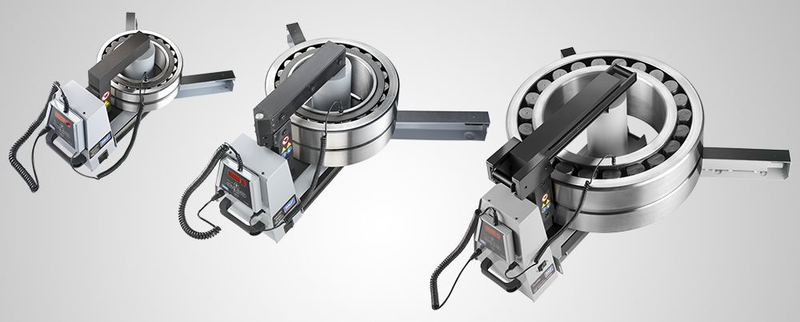

i. Induction Heater

The induction heater is the most effective way of heating bearings for hot mounting. A few tools are needed to be prepared for the induction method:

The induction heater is the most effective way of heating bearings for hot mounting. A few tools are needed to be prepared for the induction method:

- Induction Heater (of course!)

- Heat Resistant Gloves

- Yoke

How does it work?

1. A current flows in the coil of the heater which generates a magnetic field in the core.

2. This induces eddy currents in the bearing.

3. The bearing is heated due to the resistance of the bearing material to the eddy currents.

4. To relieve typical interference fit, the temperature difference between the bearing and ambient temperature is about 90°C.

Hot Tip:

| Hot Tip |

| 110°C is the recommended temperature for heating up the bearing using the induction heater method. |

ii. Electric Hot Plates and Heating Cabinets

These equipment are fairly easy to use. Set the preset temperature accordingly before heating your bearings using the equipment.

While ovens and hot plates can be used for batch heating for small bearings, their use for heating larger bearings generally will be inefficient and time-consuming.

Bearing Mounting Methods Overview

| Bearing Size | Bearing Bore | Tools Used | |

| Cold Mounting- Mechanical | Small | Cylindrical | Spanner, Socket, Fitting Tool, Hammer |

| Cold Mounting- Hydraulic/Oil Injection | Medium, Large | Tapered | Hydraulic Nut and Pump, Hook and Lock Spanner, Oil Injection |

| Hot Mounting- Induction Heater | Small, Medium, Large | Cylindrical | Induction Heater, Yoke, Gloves |

| Hot Mounting- Hot Plate/Heat Cabinet | Small | Cylindrical | Hot Plate, Heat Cabinet, Hot Oil Bath |

The precise tools and procedure required to install a bearing vary with its type, size, speed, application and industry as shown in some of the examples above. Our team of experienced engineers are here to assist you with professional consultation and recommendations for proper mounting to prolong the efficient running of equipment. Book your free consultation with us today.